Predict equipment failure before it stops production

Prevent unplanned downtime and extend the life of your critical equipment with NSK Condition Monitoring Solutions.

Request a ConsultationSmarter Bearings. Smarter Machines. Smarter Future.

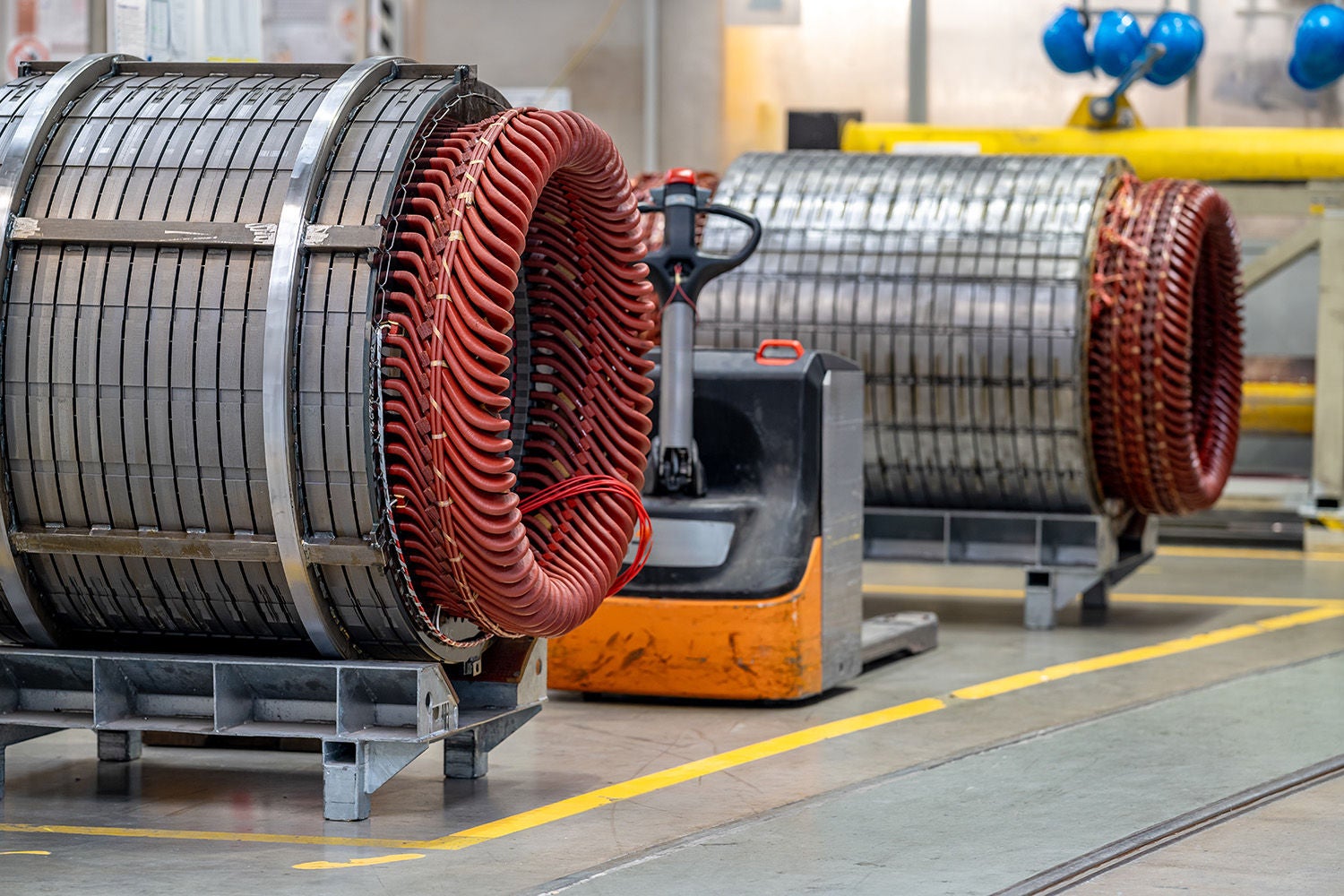

For over a century, NSK has been a trusted partner in bearings and linear motion products — the foundation of reliable machinery worldwide. Our customers rely on us for products that deliver consistent performance under the most demanding conditions.

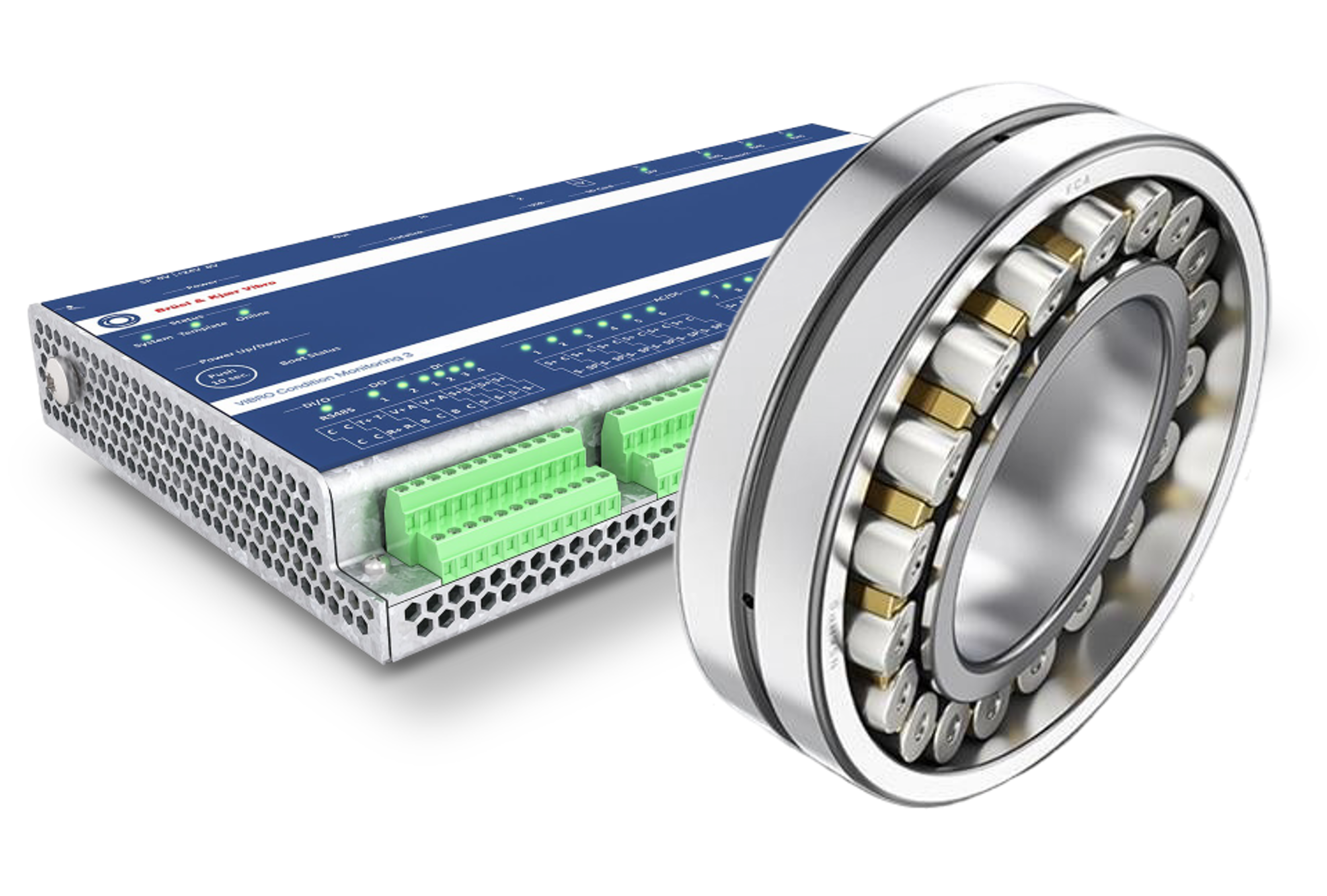

To extend that reliability even further, NSK now offers advanced condition monitoring solutions from Brüel & Kjær Vibro, part of the NSK Group and a global leader in predictive maintenance.

By combining NSK’s expertise in precision engineering with B&K Vibro’s monitoring technologies, we provide a complete lifecycle solution: robust products, enhanced by predictive intelligence, to maximize uptime and operational efficiency.

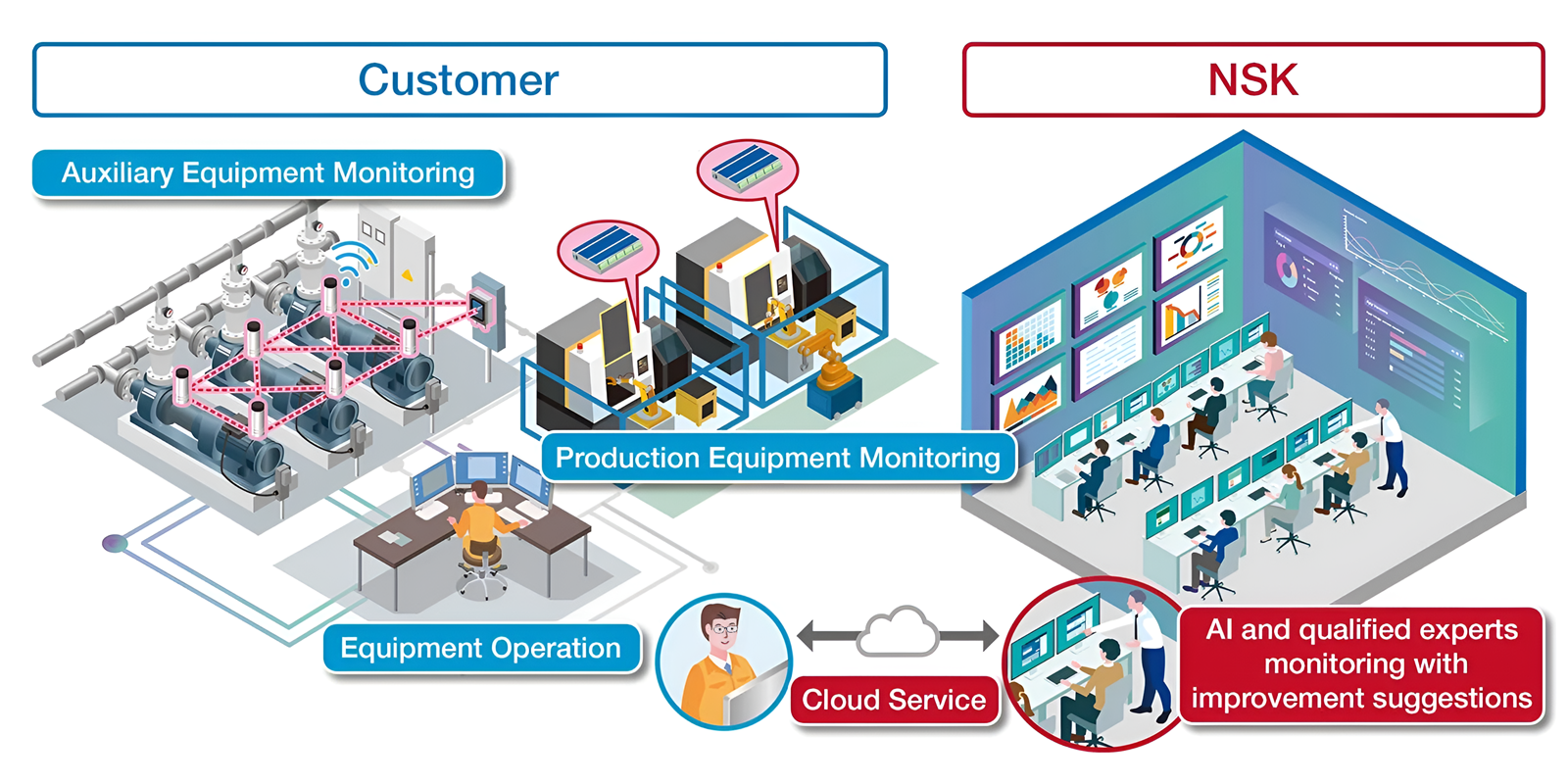

Customer equipment, secure cloud analytics, and NSK expertise working together to prevent failures.

Use Machine Data to Prevent Equipment Failure

- Capture critical machine data from rotating equipment using advanced sensors

- Analyze trends continuously through secure cloud-based monitoring

- Detect early signs of failure with AI and condition monitoring specialists

- Act with confidence using clear recommendations to reduce unplanned downtime

NSK Condition Monitoring Portfolio

A complete ecosystem of wireless sensors, online monitoring systems, portable diagnostics and machine protection — designed to work alongside NSK bearings and linear motion products to predict issues early and protect critical assets.

Cloud-based Monitoring

Our cloud-based monitoring system BKV Beyond® utilizes AI and Machine Learning to deliver continuous, expert-verified health insights, identifying root causes and actionable solutions for rotating machinery.

On-Premise Monitoring

SETPOINT is an on-premise CMS that allows for continuous data analysis for assets like Motors, Pumps, and Gearboxes maximizes asset reliability, enabling predictive maintenance to eliminate unplanned downtime and optimize performance.

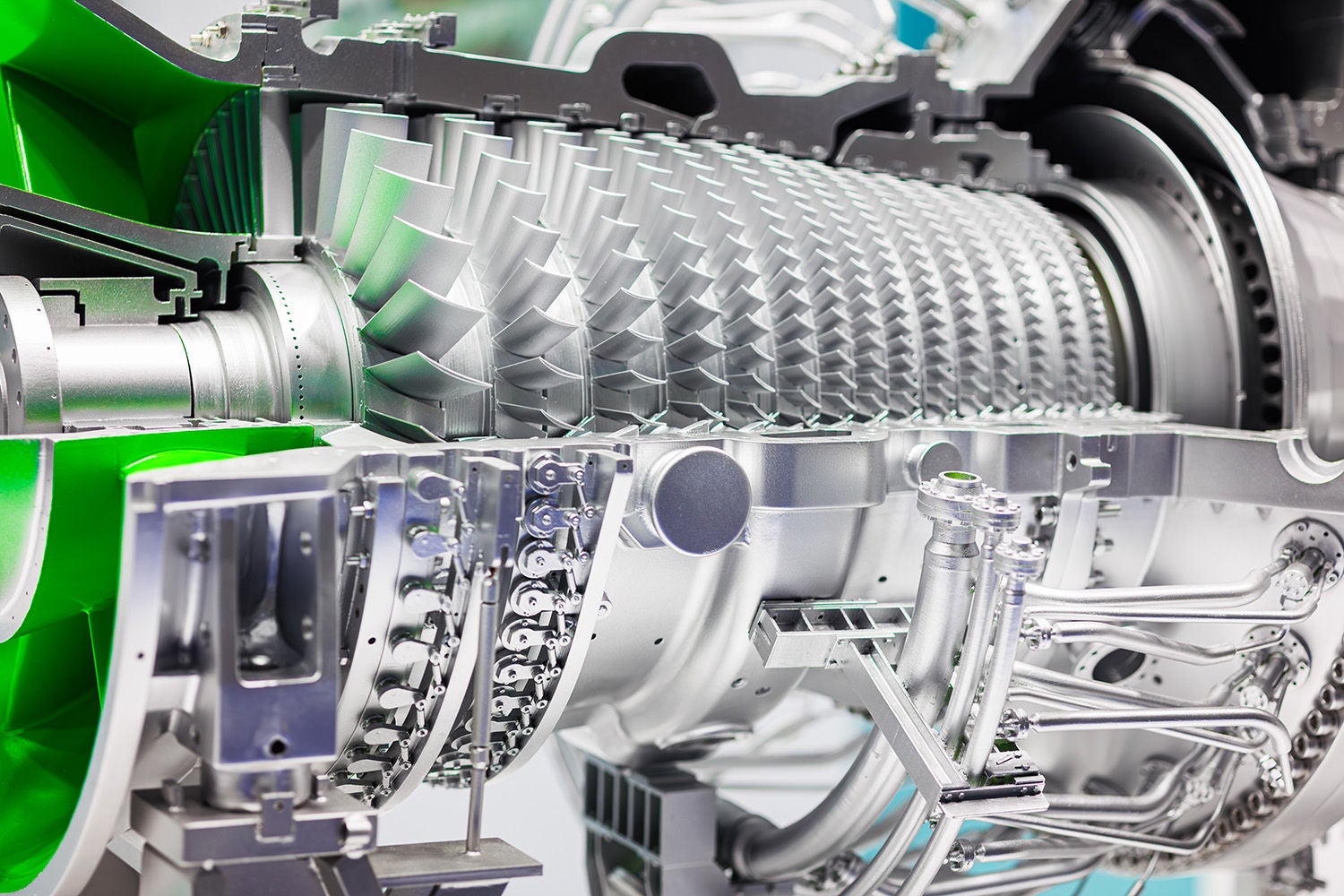

Machine Protection

Automated systems monitor critical faults on high-criticality machinery (e.g., Generators, Turbines, and Compressors), preventing catastrophic failures and ensuring HSE compliance.

Products

Core Condition Monitoring & Protection Solutions

Our core systems provide seamless, always-on asset monitoring and protection. They combine the reliability of wired sensors with the flexibility of wireless technology, creating a unified data stream for faster diagnostics and actionable insights.

Wireless Monitoring System

BKV Beyond® is a wireless, AI-enabled monitoring solution that uses smart sensors and cloud analytics to detect vibration, temperature, and process anomalies early. It helps eliminate complex cabling, provides real-time insights, and reduces downtime through predictive diagnostics and expert-verified alerts.

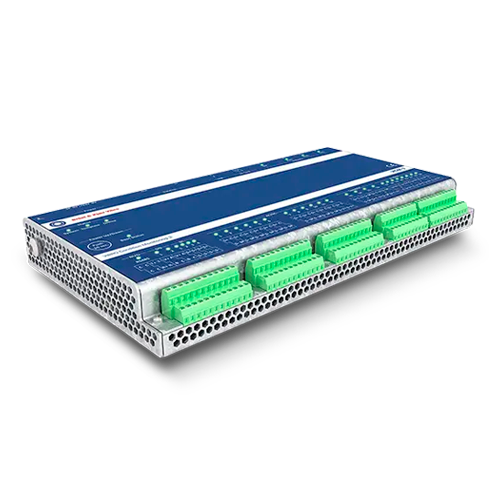

Condition Monitoring System (VCM-3)

The VCM-3 continuously measures vibration and process parameters across up to four channels, detecting imbalance, wear, or misalignment early. It integrates with AVEVA PI System™ and plant DCS platforms, offers local alarms via relays, and enables both machine protection and predictive diagnostics from a single compact unit.

VC8000

The VC-8000 is a modular, high-speed machinery protection platform designed for critical turbomachinery and heavy industrial assets. It combines advanced vibration and process monitoring with configurable rack-based modules, redundant architecture, and API 670 compliance to ensure maximum reliability, safety, and uptime in demanding environments.

Portable Monitoring Solutions

Compact, versatile tools for quick on-site diagnostics and data collection. Ideal for maintenance teams performing periodic checks, these solutions deliver actionable insights without permanent installation—perfect for multi-asset plants and service crews.

D-VibA10

The D-VibA10 is a compact, wireless vibration diagnostic tool for on-site inspection of rotating machinery. It enables quick, easy, and accurate assessment of bearing and machine health without requiring expert setup. With built-in sensors, real-time FFT analysis, and smartphone connectivity, it simplifies condition evaluation and supports predictive maintenance anywhere on the plant floor.

Vibroport 8000

The Vibroport 8000 is a modular, multi-channel vibration analyzer for advanced field diagnostics and balancing of rotating machinery. It captures high-resolution vibration and process data across multiple sensors, performs real-time analysis, and supports a wide range of condition monitoring and troubleshooting tasks — all in a robust, portable design ideal for on-site predictive maintenance.

VST-100 Data Collector

A handheld data collector for route-based vibration measurements on pumps, motors, fans and other rotating equipment, providing a simple entry point into condition monitoring programs.

4 Key Features

Built to complement NSK bearings and linear motion products — designed for plant-wide reliability.

Actionable Insights

AI-powered diagnostics and expert vibration engineers (vibration diagnosticians*) provide fact-based insights for smarter maintenance decisions.

*Machinery Condition Analyst (Vibration) in accordance with ISO 18436-2

Remote Monitoring

Reduce reliance on scarce skilled labor and minimize the need for workers in harsh or hard-to-access environments (heat, dust, or remote sites) with secure off-site monitoring.

Flexible Monitoring

From wired to wireless, continuous to periodic, our CMS adapts to your machines and operating patterns. Monitor production and auxiliary equipment across the entire plant — on-site or in the cloud — with one flexible platform.

Seamless Integration

Integrate CMS with existing plant management systems like AVEVA™ PI System™ for QA and advanced diagnostics.

*AVEVA PI System are trademarks/registered trademarks of AVEVA Group plc in the UK and other countries.

Choose the Monitoring Model That Fits Your Organization

Whether you want a fully managed service or prefer to analyze data in-house, NSK offers flexible condition monitoring options.

BKV Beyond® – Fully Managed Cloud Monitoring

If you prefer a hands-off solution and want our experts to manage diagnostics and recommendations for you, BKV Beyond® is a cloud-based platform where wireless and online systems stream vibration and process data for continuous monitoring.

B&K Vibro specialists review the data, verify alarms, identify root causes, and provide clear maintenance recommendations — enabling predictive maintenance without the need for in-house condition monitoring expertise.

SETPOINT CMS – On-Premise, AVEVA™ PI System™-Powered

For plants that prefer to analyze condition data in-house, Setpoint CMS provides an on-premise condition monitoring solution that stores vibration and process data directly in the AVEVA™ PI System™ historian you already use.

This approach eliminates separate CM databases, maintains a single source of truth, and gives reliability and maintenance teams the advanced diagnostic tools they need — while keeping full control of data, analytics, and decision-making within the plant.

Success Story

NSK and Brüel & Kjær Vibro collaboration delivered Zero Unplanned Downtime on a Critical Fan Application

Background:

- An oven fan at a pharmaceutical site showed a continuous rise in Bearing Condition levels through VCM-3 and SETPOINT CMS.

- After a clear defect frequency appeared, the site replaced both motor bearings, but the condition alarms re-emerged.

- NSK's RCA confirmed electrical discharge damage—raceway fluting and rolling-element pitting.

- To protect production, the customer replaced the fan, and the combined diagnostics support from B&K Vibro and NSK ensured zero unplanned downtime.

ROOT CAUSE IDENTIFIED

Electrical Discharge Damage

ZERO UNPLANNED DOWNTIME

Saving Time and Money

Assets We Protect

NSK CMS applies across industries by focusing on the rotating assets that matter most:

Pumps

Process, cooling, feed and circulation pumps.

Motors

LV and MV motors driving critical equipment.

Gearboxes

Speed-reduction and transfer gear units.

Compressors

Reciprocating and centrifugal compressors.

Fans & Blowers

Process, cooling and ventilation fans.

Wind Turbines

Main bearings, gearboxes and generators in onshore fleets.

Steam, Hydro & Gas Turbines / Generators

Power generation assets where availability is critical.

Paper Machine Rolls & Other Critical Rotating Equipment

High-speed, high-load assets where bearing health drives quality.

Driving Sustainability & Future Innovation

Condition monitoring extends beyond equipment reliability — it is also a key enabler of environmental performance. By detecting inefficiencies and extending equipment life, our CMS helps industries:

- Cut CO₂ emissions by reducing energy waste

- Conserve resources through repair and reuse of machinery

- Accelerate renewable energy adoption with reliable wind turbine monitoring

Looking ahead, NSK and B&K Vibro are driving innovation with:

- BKV Beyond — a cloud-based, AI-enabled monitoring platform with wireless sensors for scalable, predictive insights

- Linear Motion Monitoring — advanced diagnostics for NSK ball screws and linear guides, enabling real-time detection of deterioration in machine tools and automation systems

Frequently Asked Questions

Practical answers for engineers, maintenance teams, and operations leaders.

No. While CMS is a natural extension of NSK bearings and motion products, our condition monitoring systems can be applied to a wide range of machinery and equipment.

Yes. Our solutions integrate seamlessly with platforms like the AVEVA™ PI System™ and can be adapted to most existing IT/OT environments without major system overhauls.

NSK CMS uses encrypted communication protocols and secure cloud infrastructure (for BKV Beyond) to ensure sensitive operational data is protected.

Our systems are designed to deliver clear, actionable reports. Even if your team doesn’t have vibration specialists, our diagnostic services and certified analysts provide expert support when needed.

No — it optimizes it. With CM, you don’t waste time servicing equipment too early, and you avoid the risk of waiting too long. Instead, you schedule maintenance exactly when it’s needed, based on real-time data.

We offer training, technical support, and ongoing diagnostic services. Customers can choose between periodic reporting or continuous monitoring service packages.

NSK specialists work with you to assess equipment criticality, operating environment, and maintenance goals. Based on that, we recommend either remote continuous monitoring or portable solutions for periodic checks.

Contact our experts to discover how NSK's condition monitoring solutions can optimize your operations.

Talk to an NSK Specialist today.

Combine world-class bearings with advanced condition monitoring to extend bearing life, reduce downtime, and protect critical assets.

Talk to an NSK Specialist today.

Combine world-class bearings with advanced condition monitoring to extend bearing life, reduce downtime, and protect critical assets.

Prefer a faster response?

Chat with us: click the chat bubble in the bottom-right corner to start a live chat.

Available Monday–Friday, 9 AM – 5 PM (Eastern Time)

Contact our experts to discover how NSK's condition monitoring solutions can optimize your operations.

Share